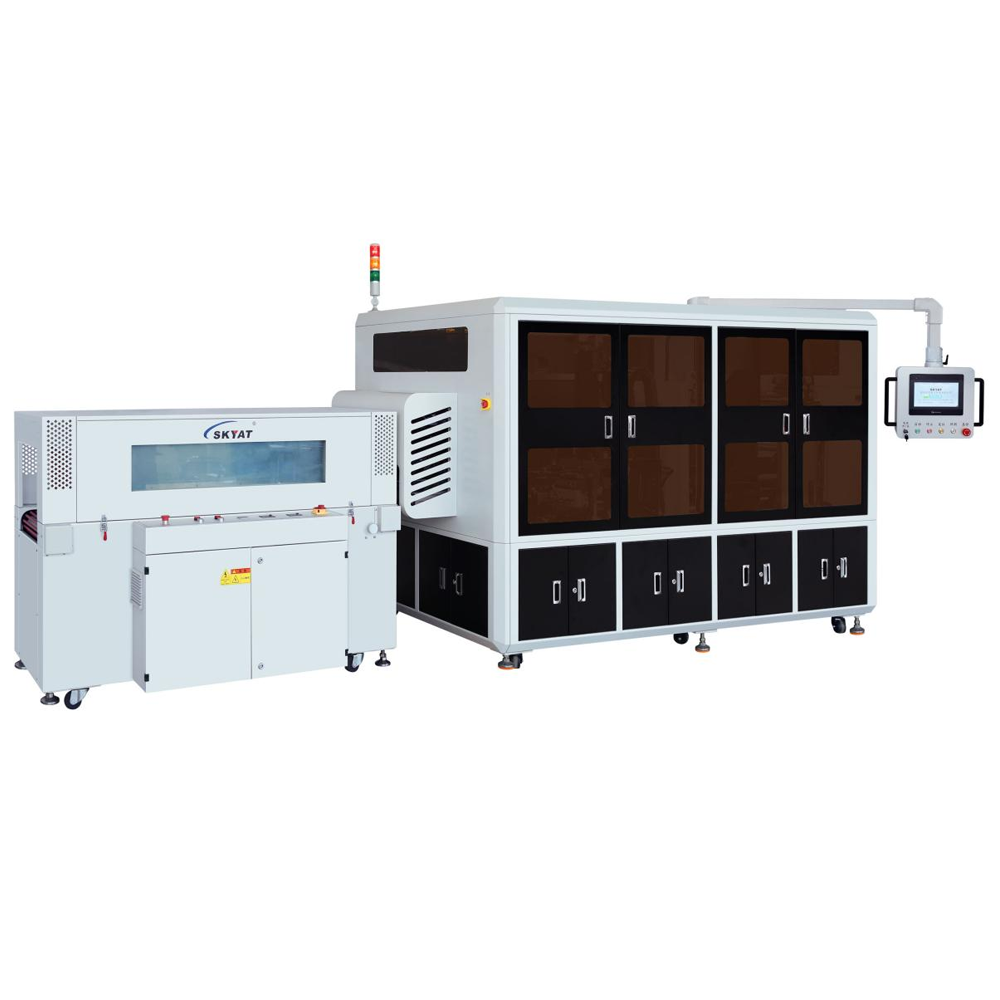

Middle-seal Corner-cutting Wrapping Machine

The corner cutting and coating machine is used for the outer film of various product packaging boxes and anti-counterfeiting outer film packaging.

(The corner cutting and coating machine) is a full-scale coating for various color boxes, 360° without dead angles, without corner wrinkles.

The packaging efficiency is 650-1200 pieces/hour, which improves efficiency and reduces costs.

The product packaging quality is guaranteed, and the yield rate reaches 99%, making the packaging film cutting line quality excellent and precise.

- Overview

- Parameter

- Recommended Products

Equipment introduction:

The corner cutting and coating machine is used for the outer film of various product packaging boxes and anti-counterfeiting outer film packaging.

(The corner cutting and coating machine) is a full-scale coating for various color boxes, 360° without dead angles, without corner wrinkles.

The packaging efficiency is 650-1200 pieces/hour, which improves efficiency and reduces costs.

The product packaging quality is guaranteed, and the yield rate reaches 99%, making the packaging film cutting line quality excellent and precise.

Equipment functions:

a. The equipment automatically wraps the POF shrink film on the surface of the product box. Because the POF shrink film has high transparency and good gloss, it can clearly show the appearance of the product, improve sensory awareness, and reflect high-end quality;

b. The equipment automatically wraps the POF shrink film to ensure the consistency and reliability of packaging quality;

c. The equipment automatically wraps the POF shrink film faster and with better quality than traditional manual wrapping, which improves production efficiency, saves production costs, and improves the company's competitiveness;

d. The equipment can achieve universality and one-button product switching through servo drive position parameter adjustment and manual adjustment of the film pulling rod.

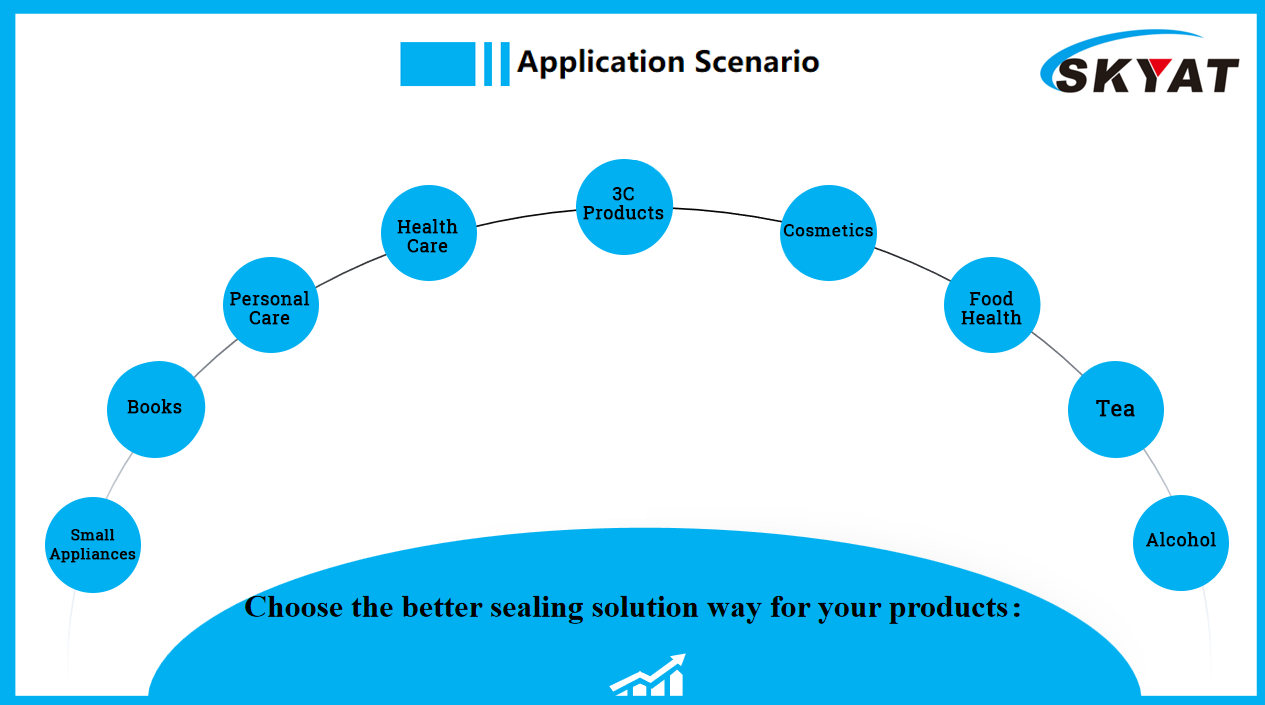

Application Scenario

This corner cutting and laminating machine is suitable for: 3C products, tea, wine, small appliances, personal care, health care and food health, cosmetics, books and other products.

- 3C: mobile phones, drones, TWS headphones, smart watches, VR glasses, smart speakers, electronic cigarettes, smart small appliances, etc.

- Personal care: electric toothbrushes, razors, hair dryers, etc.

- Health care and food health: tea gift boxes, health care gift boxes, medicine and health gift boxes, massagers, liquor, etc.

- Cosmetics: skin care gift boxes, lipstick boxes, etc. (List only part)

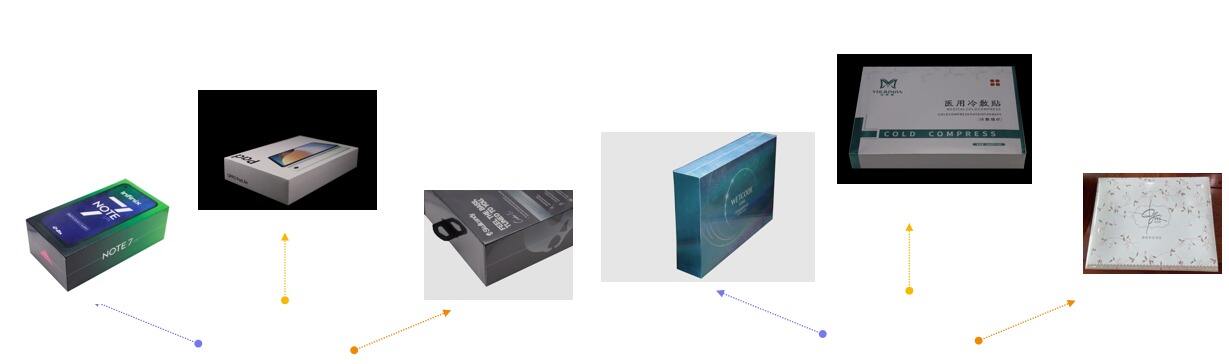

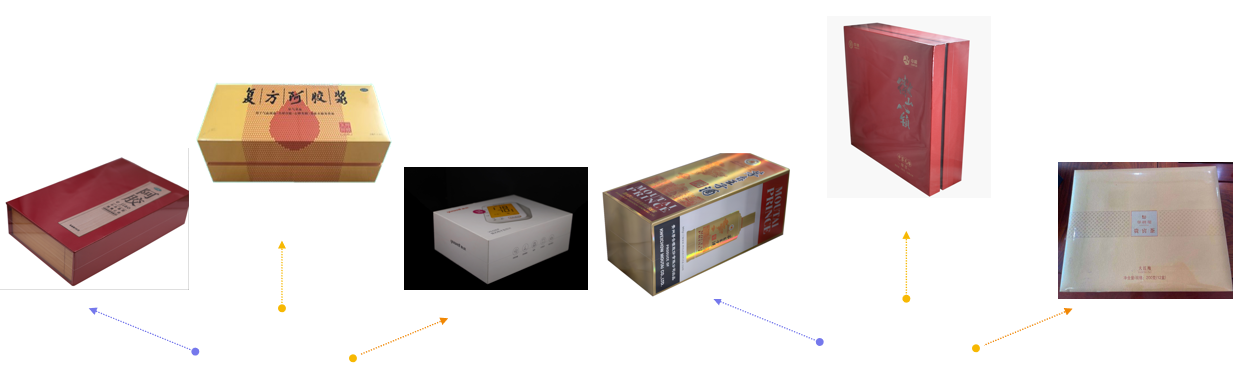

Sample

| 3C | Cosmetics |

| Books | Small Appliances |

| Healthcare | Foods & Healthcare |

Parameter

Introduction to Equipment Technical Parameters and Key component configuration:

| 1.General technical parameters of equipment | |||

| Height |

Feed 750mm±25mm Discharge 837mm±25mm |

Power supply | single phase AC220V 20A 50HZ |

| Control system | PLC+HMI | Air source | 0.6~0.8Mpa |

| Language | Simplified Chinese/English | Power | Single bag 7.5kW |

| Packaging film material | POF | Double bag 9.6kW | |

| Sealing and cutting temperature | 150~230 | Production yield | >99% |

| 2. Configuration of key equipment components | |||

| Serial Number | Key component name | Brand | Remarks |

| 1 | Frame | / | Square welded frame, painted sheet metal shell, and transparent acrglic window |

| 2 | Knife, lining plate | / | SKDll material cutting knife, high-temperature rubber strip lining |

| 3 | Lead serew | HIWIN | |

| 4 | Cylinder, solenoid valve, quick connector | AIRTAC | |

| 5 |

Door magnetic switch, photoelectric sensor or |

OMRON/Panasonic | |

| 6 | Control system | PLC+HMI | |

| 7 | Operation panel | Weilentong | |

Intelligent center-sealing laminating machine series:

|

Number |

Equipment model |

Project code |

Equipment use range/mm ml;/ |

Sealing knife length/mm |

||||

|

Length |

Width |

Height |

Bag making knife |

Sealing knife |

Corner knife |

|||

|

1 |

Gripper-carrying center-sealed corner-cutting laminating machine |

QB22S |

100~250 |

70~250 |

30~120 |

480 |

400 |

170 |

|

2 |

QB33S |

100~350 |

70~300 |

30~120 |

580 |

450 |

170 |

|

|

3 |

QB43S |

100~450 |

70~350 |

30~120 |

680 |

500 |

170 |

|

|

4 |

Line-carrying center-sealed corner-cutting laminating machine |

QL22S |

100~250 |

70~250 |

30~120 |

480 |

400 |

170 |

|

5 |

QL33S |

100~350 |

70~300 |

30~120 |

580 |

450 |

170 |

|

|

6 |

QL43S |

100~450 |

70~350 |

30~120 |

680 |

500 |

170 |

|

Main technical parameters of the equipment:

|

Working height |

Feed 725mm±25mm |

Power supply |

Single Phase AC220V 62A 50HZ |

|

Discharge 843mm±25mm |

Total Power KW |

9KW |

|

|

UPH |

800Pcs~1200Pcs |

Air source |

0.6~0.8Mpa |

|

Production yield |

>98% |

Gas consumption |

1.2㎡/min |

|

Control System |

PLC+HMI |

Language |

Simplified Chinese/English |

|

Packaging film material |

Cross-linked POF thickness: 0.19mm |

Cutting knife temperature ℃ |

150-230℃ |