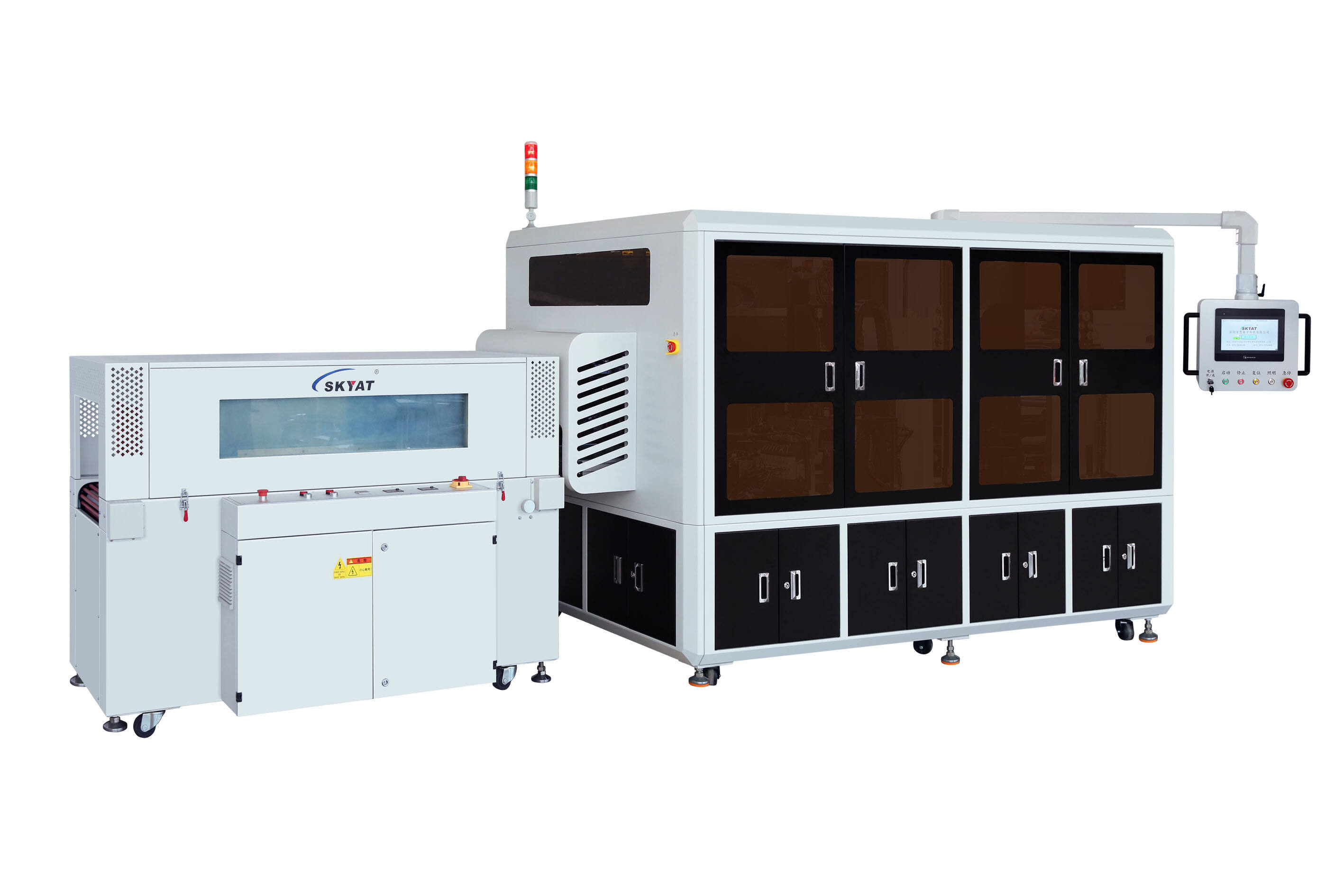

A shrink wrap packaging machine is a pivotal asset in modern packaging lines, designed to wrap products in shrinkable film and apply heat to create a tight, protective seal that enhances both protection and presentation. This machine caters to a wide range of industries, from electronics manufacturing where it secures circuit boards and components, to cosmetics brands seeking sleek, transparent packaging for their products. Its versatility allows it to handle various product sizes and shapes, from small health supplements bottles to large new energy equipment parts. Equipped with adjustable heat settings and conveyor speeds, this machine ensures optimal shrinking for different film types, including PVC, POF, and PE. For tea producers, POF film is a popular choice as it is food-safe and preserves freshness, while PE film is ideal for steel hardware due to its durability. In the gaming industry, it wraps collector’s edition boxes with precision, ensuring a wrinkle-free finish that appeals to consumers. The automotive manufacturing sector relies on it to bundle small parts, reducing the risk of loss during transit. Modern shrink wrap packaging machines come in semi-automatic and fully automatic models. Semi-automatic versions are suitable for small to medium-sized businesses, such as ceramic industry workshops, while fully automatic ones integrate seamlessly into high-volume production lines, like those in drone manufacturing facilities. They also contribute to sustainability efforts by minimizing film waste through precise cutting and application. Whether used for retail display or shipping, this machine ensures products remain protected from dust, moisture, and damage, making it an indispensable tool for businesses aiming to optimize their packaging processes.

Copyright © 2025 By Skyat Limited. - Privacy policy