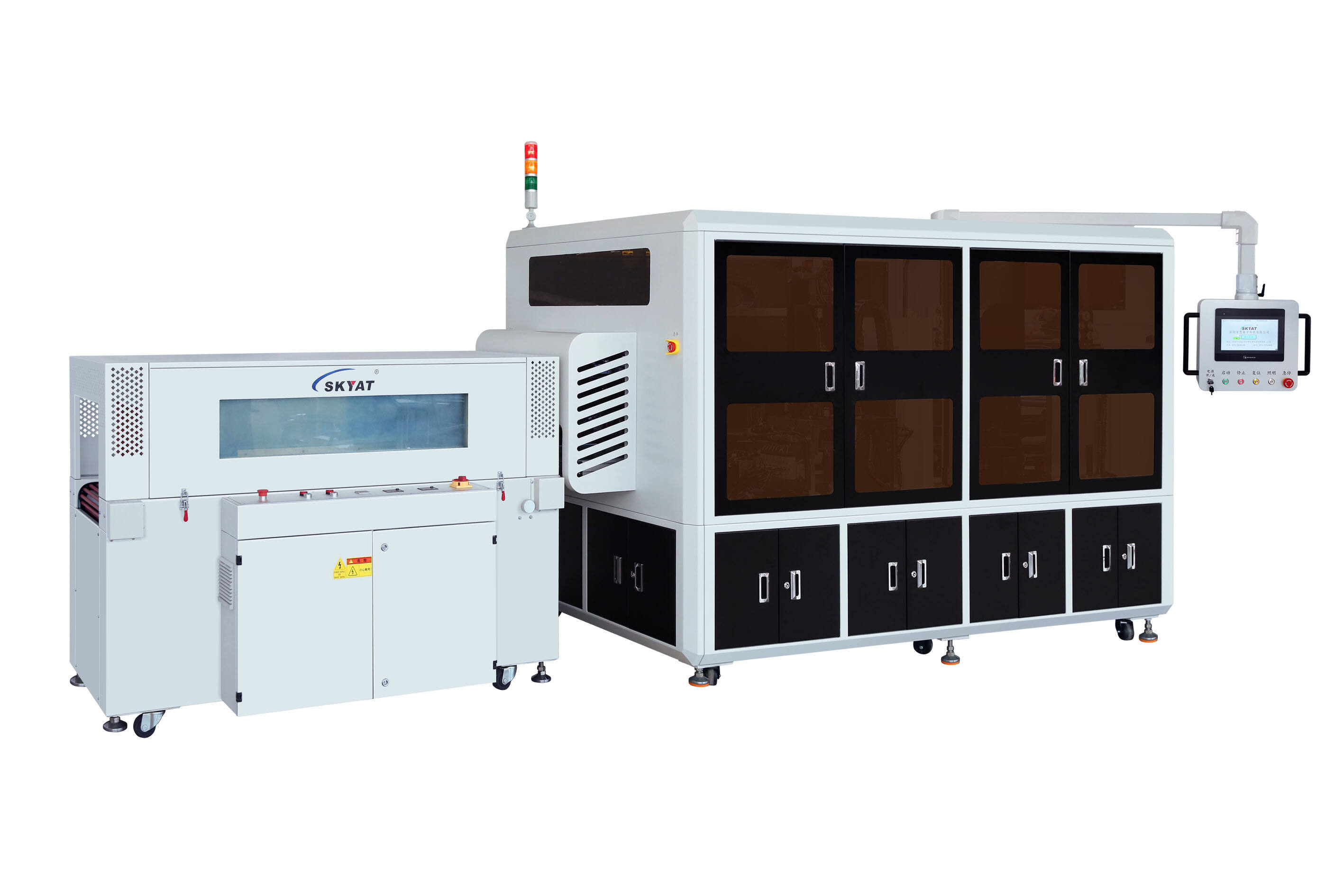

A heat shrink machine is a powerful packaging tool that uses controlled heat to shrink plastic film around products, forming a tight, protective layer that conforms precisely to their shape. This machine is widely used across industries, from electronics manufacturing to apparel industry, providing a versatile solution for securing and presenting products. Its ability to create a snug fit makes it ideal for irregularly shaped items, such as drone components, ceramic industry crafts, and automotive manufacturing parts, ensuring they remain stable during transit. Heat shrink machines come in various configurations, including tunnel-style models for high-volume production and handheld units for small-scale tasks. Tunnel machines, with their conveyor belts and evenly distributed heat, are perfect for new energy equipment manufacturers wrapping solar panel parts or gaming industry facilities packaging console bundles. Handheld heat guns, often paired with manual sealers, suit small businesses like tea shops or health supplements boutiques, offering flexibility for low-volume packaging. These machines work with multiple film types, each tailored to specific needs: PVC for cost-effective packaging of smart electronics accessories, POF for food-safe wrapping of tea packets, and PE for durable protection of steel hardware. Adjustable temperature settings prevent overheating, ensuring heat-sensitive items like cosmetics or printed materials retain their quality. By reducing packaging bulk and enhancing product visibility, a heat shrink machine not only improves logistics efficiency but also boosts shelf appeal, making it a valuable asset for businesses aiming to balance protection and presentation.

Copyright © 2025 By Skyat Limited. - Privacy policy