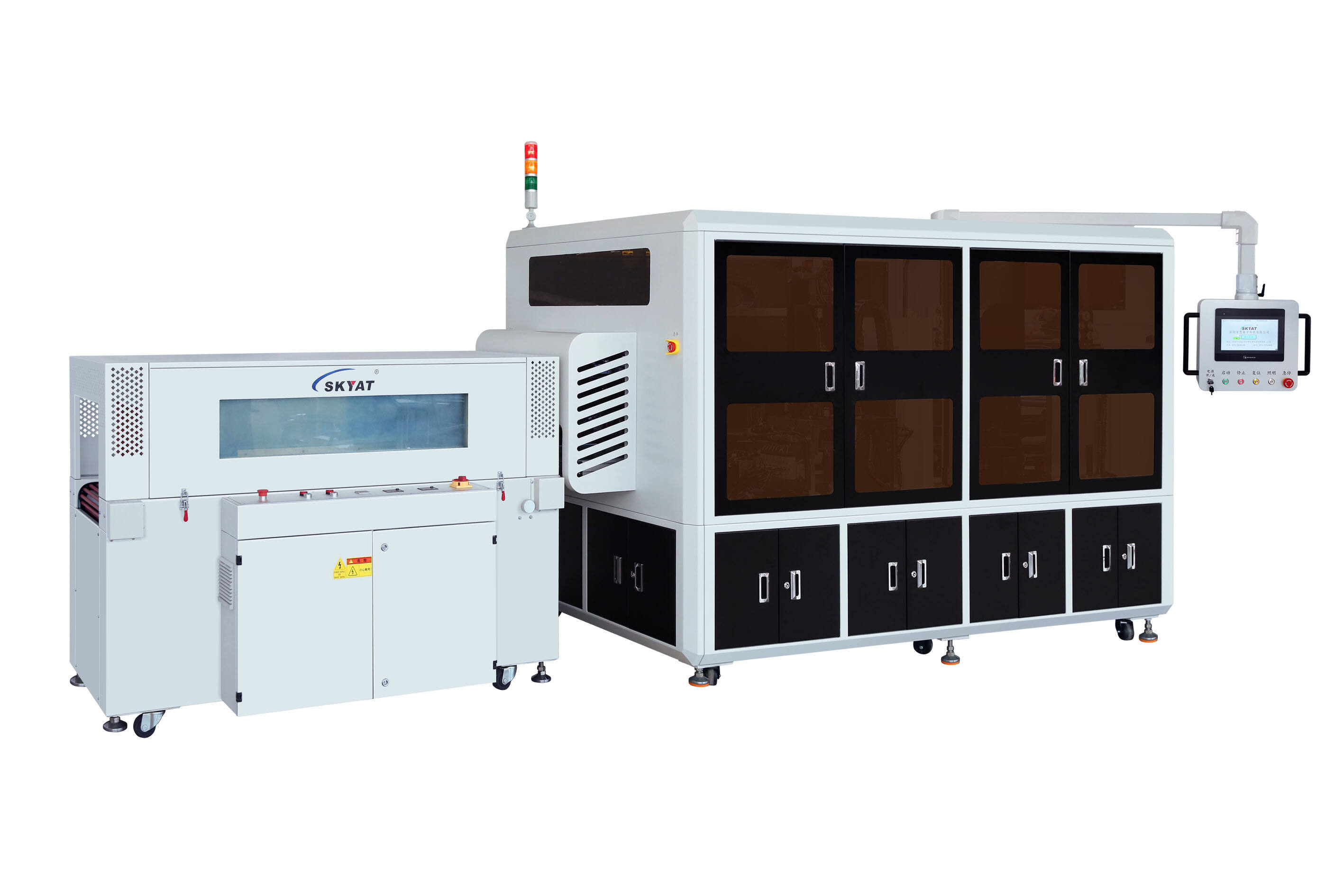

An automatic shrink packaging machine is a cutting-edge solution designed to streamline high-volume packaging processes, combining speed, precision, and reliability to meet the demands of diverse industries. This machine automates every step, from feeding products onto the conveyor to wrapping them in shrink film and applying controlled heat for a tight, uniform seal. It is widely used in electronics manufacturing for packaging circuit boards and devices, ensuring they are protected from dust and damage during shipping. In the cosmetics industry, it wraps luxury skincare sets with a sleek finish, enhancing shelf appeal and brand perception. Equipped with advanced sensors and programmable controls, this machine adapts seamlessly to varying product sizes and shapes, from small health supplements bottles to large new energy equipment components. It works with multiple film types, including PVC, POF, and PE, allowing customization based on industry needs. For tea producers, POF film is preferred for its food-safe properties, while PE film is ideal for steel hardware due to its durability. The machine’s high throughput—often up to 200 items per minute—makes it indispensable for automotive manufacturing plants bundling parts and gaming industry facilities packaging collector’s editions during peak seasons. Additional features like automatic film feeding, precise temperature regulation, and energy-saving modes reduce waste and operational costs. It integrates smoothly with existing production lines, making it a valuable asset for ceramic industry workshops scaling operations and drone manufacturers requiring consistent, high-quality packaging. Whether used for retail display or bulk shipping, an automatic shrink packaging machine ensures products remain secure, presentable, and protected, driving efficiency and customer satisfaction across countless sectors.

Copyright © 2025 By Skyat Limited. - Privacy policy