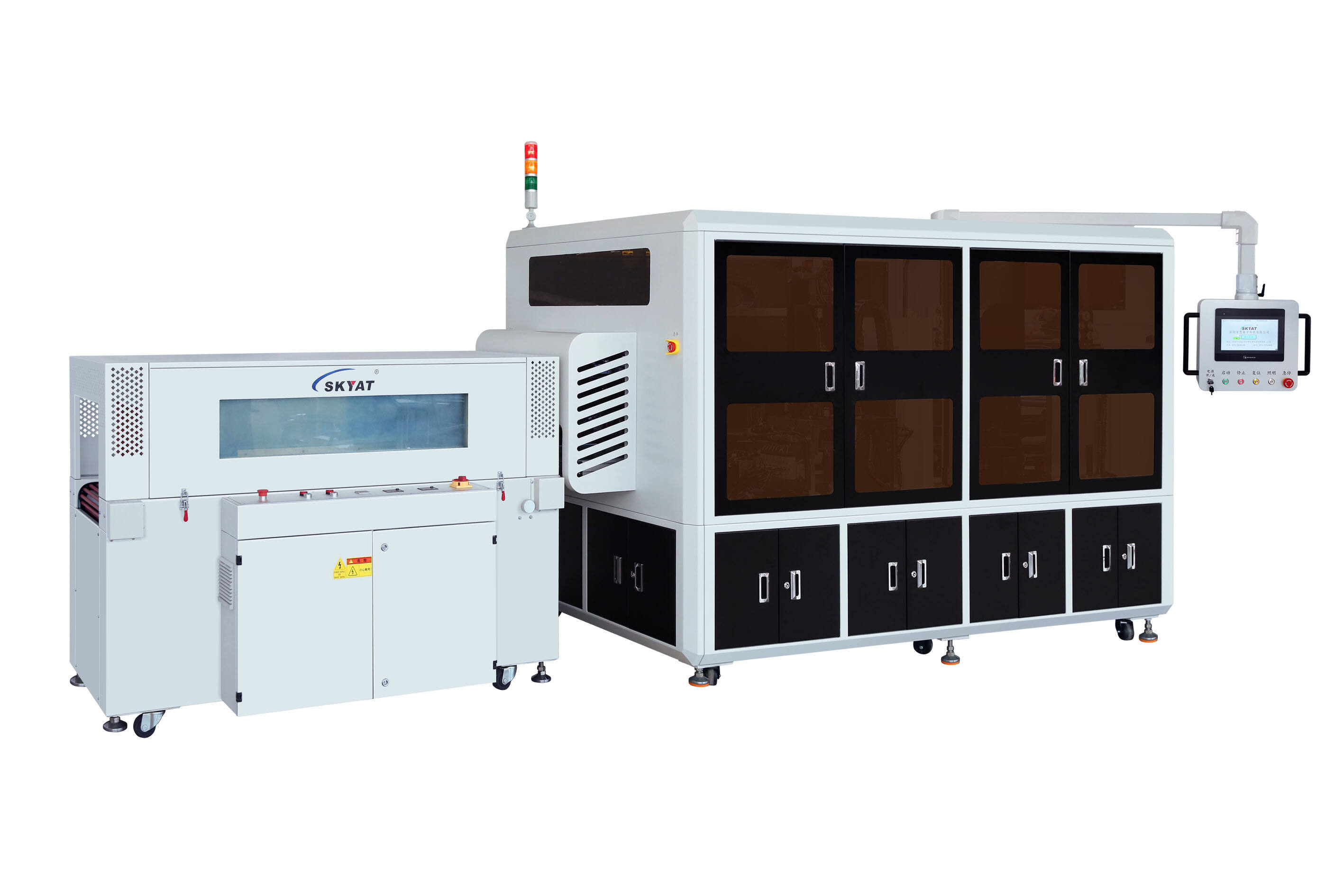

Automated shrink wrap machines represent the pinnacle of packaging efficiency, combining advanced technology with high-performance capabilities to handle large-scale packaging needs across industries. These machines are indispensable for electronics manufacturing facilities producing smart electronics devices, automotive manufacturing plants bundling parts, and new energy equipment manufacturers wrapping solar panels. Their ability to operate continuously, with minimal human intervention, ensures consistent quality and maximizes throughput—often exceeding 200 items per minute. Equipped with sophisticated sensors and AI-driven controls, automated shrink wrap machines can detect product dimensions in real time, adjusting film length, heat levels, and conveyor speed to ensure a perfect fit. This adaptability makes them ideal for diverse products, from small health supplements tablets to large steel components and irregularly shaped drone bodies. They support multiple film types, including eco-friendly options, aligning with sustainability goals in apparel industry and tea production. In the cosmetics industry, these machines wrap luxury products with precision, creating a premium finish that attracts consumers. For gaming industry companies, they handle seasonal spikes in demand, packaging collector’s editions efficiently. ceramic industry businesses benefit from gentle handling features that prevent damage to fragile items. Additional perks include remote monitoring, predictive maintenance alerts, and integration with ERP systems, reducing downtime and operational costs. Whether used for retail or industrial packaging, automated shrink wrap machines deliver unmatched efficiency, reliability, and cost-effectiveness, making them a cornerstone of successful manufacturing operations.

Copyright © 2025 By Skyat Limited. - Privacy policy