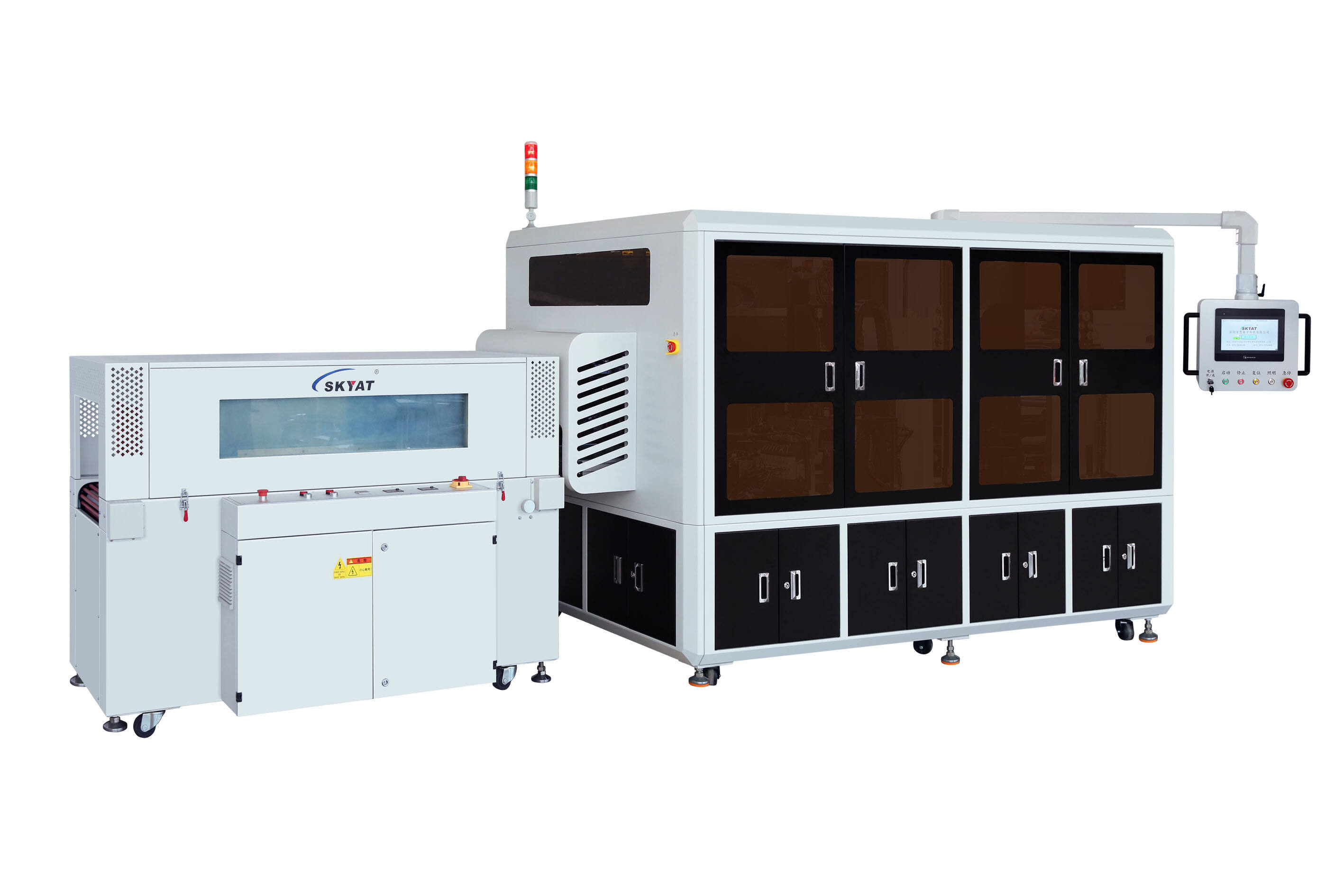

The price of a shrink wrap machine varies depending on several factors, including its automation level, production capacity, and additional features, making it accessible to businesses of all sizes across industries. Entry-level manual shrink wrap machines, ideal for small operations like tea shops and ceramic industry craft studios, are available at a budget-friendly price. These machines require manual film feeding and sealing, making them suitable for low-volume packaging needs, such as wrapping small health supplements boxes or cosmetics samples. Mid-range semi-automatic shrink wrap machines come with a higher price tag, offering features like automatic film cutting and adjustable heat settings. They are popular among smart electronics accessory manufacturers, gaming industry small businesses, and drone part suppliers, as they can handle moderate production volumes up to 50 items per minute with greater efficiency. These machines reduce manual labor and improve consistency, making them a worthwhile investment for growing businesses. High-end fully automatic shrink wrap machines, designed for large-scale operations in electronics manufacturing, automotive manufacturing, and new energy equipment plants, have the highest prices. They boast advanced capabilities, such as integration with production lines, high-speed operation 100+ items per minute, and compatibility with various film types PVC, POF, PE. Customizations, such as specialized conveyors for steel parts or food-safe components for food processing, can further increase the cost. When considering the price, it’s important to factor in long-term benefits. Higher-priced machines often reduce film waste, lower maintenance costs, and increase productivity, leading to a better return on investment over time. Many suppliers also offer flexible payment options and after-sales support, ensuring businesses can find a machine that fits their budget and operational needs.

Copyright © 2025 By Skyat Limited. - Privacy policy