Corner cutting and film coating machine: intelligent packaging solution for modern production lines

In today's fast-paced industrial production environment, the efficiency and quality of the packaging process directly affect the market competitiveness and economic benefits of enterprises. As a key equipment in the packaging process, the corner cutting and film coating machine is becoming the preferred packaging solution for more and more companies with its excellent performance and intelligent characteristics. It can not only greatly improve packaging efficiency, but also ensure the safety and integrity of products during transportation and storage.

01 High-efficiency productivity: a new benchmark for smart manufacturing

Modern corner cutting and film coating machines represent the highest level of packaging automation technology. Compared with traditional manual packaging, its advantages are mainly reflected in the following aspects:

- Amazing changeover speed: intelligent corner cutting and film coating machines are suitable for boxes of different models, fully automatic operation, it only takes a few minutes to establish a new formula, and it only takes a few seconds to adjust the formula, saving time and effort.

- Continuous operation capability: it can be connected to the assembly line to achieve 24-hour uninterrupted production. It is particularly suitable for packaging needs during peak order periods such as e-commerce promotions and holiday seasons.

- Energy-saving and consumption-reducing design: the servo drive system and intelligent power regulation technology are used, and the energy consumption is reduced by 40% compared with traditional models, saving enterprises considerable operating costs.

- Flexible adaptability: through modular design, packaging molds of different specifications can be quickly switched to meet the flexible production needs of multiple varieties and small batches.

02 Precise quality control: technology empowers perfect packaging

Stable and reliable operation, key components use imported brands, and the average trouble-free operation time exceeds 5,000 hours, ensuring the continuous and stable operation of the production line.

03 Humanized operation: simple experience in the intelligent era

While maintaining high performance, the modern corner cutting and wrapping machine has also been fully optimized in terms of operating experience:

- Intelligent interactive interface: The touch screen is equipped with a simple operating system, supports multi-language switching, and the operating logic is intuitive and clear.

- One-touch switching: Multiple packaging solutions are preset, and product switching can be completed by simply touching the screen, greatly reducing the difficulty of operation.

- Remote monitoring and maintenance: Remote monitoring of equipment status, fault warning and diagnosis functions can detect potential problems in advance.

- Safety protection system: Equipped with multiple safety protection devices, including emergency stop buttons, to ensure the safety of operators.

04 Industry application expansion

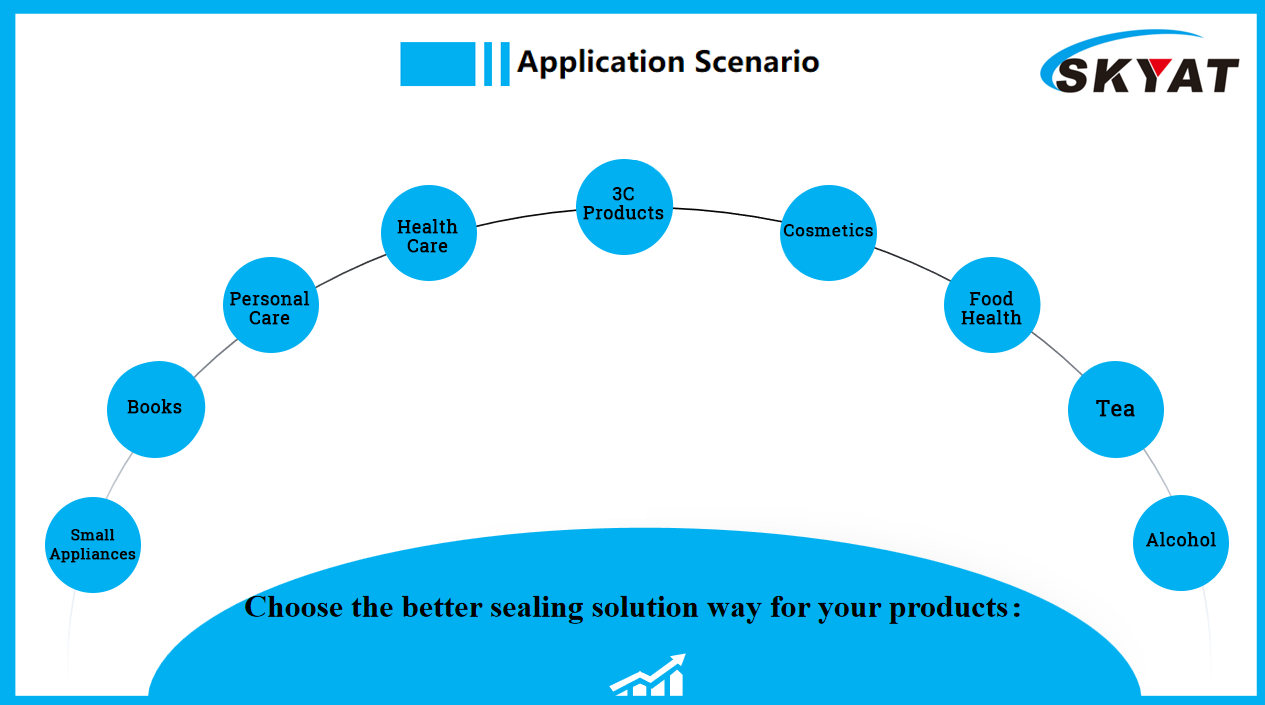

The application field of corner cutting and coating machines is constantly expanding:

- Electronic products: packaging of precision equipment such as mobile phones and tablets

- Medicine and health care: outer packaging of medicine boxes and medical devices

- Food and beverages: high-end gift boxes, outer packaging of snacks

- Daily chemicals: exquisite packaging of cosmetics and skin care products

This corner cutting and laminating machine is suitable for: 3C products, tea, wine, small appliances, personal care, health care and food health, cosmetics, books and other products.

- 3C: mobile phones, drones, TWS headphones, smart watches, VR glasses, smart speakers, electronic cigarettes, smart small appliances, etc.

- Personal care: electric toothbrushes, razors, hair dryers, etc.

- Health care and food health: tea gift boxes, health care gift boxes, medicine and health gift boxes, massagers, liquor, etc.

- Cosmetics: skin care gift boxes, lipstick boxes, etc. (List only part)

Skyat Limited as a leading enterprise in the high-end packaging equipment industry, has been focusing on the research and development and innovation of intelligent corner cutting and film coating machines for more than ten years. We are well aware that in today's fierce market competition, efficient packaging solutions are crucial to the development of enterprises.

Our product advantages are reflected in:

- Independently developed core control system

- High-quality mechanical structure

- Perfect after-sales service system

- Continuous technical upgrade guarantee

Choosing Skyat, you get not only a piece of equipment, but also a complete set of intelligent packaging solutions. We look forward to working with you to create a new era of intelligent packaging.